Many brands, both large and small, tend to use Pre-Order and Back-Order interchangeably. However there are some major differences between the two, both in how a customer needs to be communicated, and how the seller can receive and fulfil those orders.

Generally speaking, Pre-Orders should be thought of as orders that can be taken on planned inventory for a product that has not arrived and cannot be purchased over that planned amount. While Back-Orders are purchases received against an item that does not have intended inventory, it’s at quantity zero (0) and creates a negative inventory number to be fulfilled. Back-Order is also the technical status a brand would use for “made to order” items.

Table of contents

Pre-Order

Purchasing a Preview of Inventory Ordered:

When a business wants to sell a product to a customer before they have the inventory On-Hand (OH) they place the item on their website for pre-order. This status of a product allows a customer to know there will be a longer than standard shipment window, and there is a potential it would not be delivered. It also allows a customer to have an item expected that may be in a limited quantity or a highly anticipated delivery. For the business this allows a longer lead time to sell the product or sell alongside a collection if a portion at large has been delayed from the bulk.

Back-Order / Made-to-Order

Purchasing inventory that counts backward from zero (0):

Unlike pre-order, back-order products do not have a planned inventory. Generally the business does not have an order already pending in the future that they can put an estimate to the shipment. This is also the inventory method used for “made to order” products, but with the addition of a general lead and creation date/production-time.

Comparing Pre-Order to Back-Order

| Pre-Order | Back-Order |

|---|---|

| Product has expected inventory arriving but is currently “out of stock” | Product was once in-stock or never will have pre-determined stock |

| Has a future inventory or a sub-quantity of what will be delivered to reduce the full sell-through. (i.e. 50 have been delivered, but only 10 are on pre-order, preventing the item from being out of stock when it arrives) | Product is now at 0 inventory but has a future inventory |

| Inventory will be decremented against future inventory, but cannot sell more than the future estimate | Creates negative inventory value when purchased, and when inventory is received decrements from that received value and can continue to go into the negative |

| Has a known expected shipping date (promise date) | Has no expected shipping date, but could provide a wide estimate |

| Reserves customer payment funds, and charges customer at time of shipment | Charges customer at time of purchase(this depends on your rules; you could also just reserve funds) |

| Need to notify customers if there is a delay | Need to refund customers if order will not be fulfilled |

| In the US follows FTC’s “Prompt Delivery” rule* please consult your expert on their rules:Has a promise date of shipmentNotifies customer within 24 hours if delayed to promise dateHas 30 days after promise delay to ship the productAuto cancel and refund if not able to meet delivery after 30 days of promise delayOnly charges customers when the product has been shipped | In the US following “Mail Order, Internet or Telephone Order” FTC’s rule * please consult your expert on their rules:A reason must be given for the delayItems cannot be substituted if unable to be filledOrder must be canceled and refunded if has not shipped prior to 30 days of original promise date |

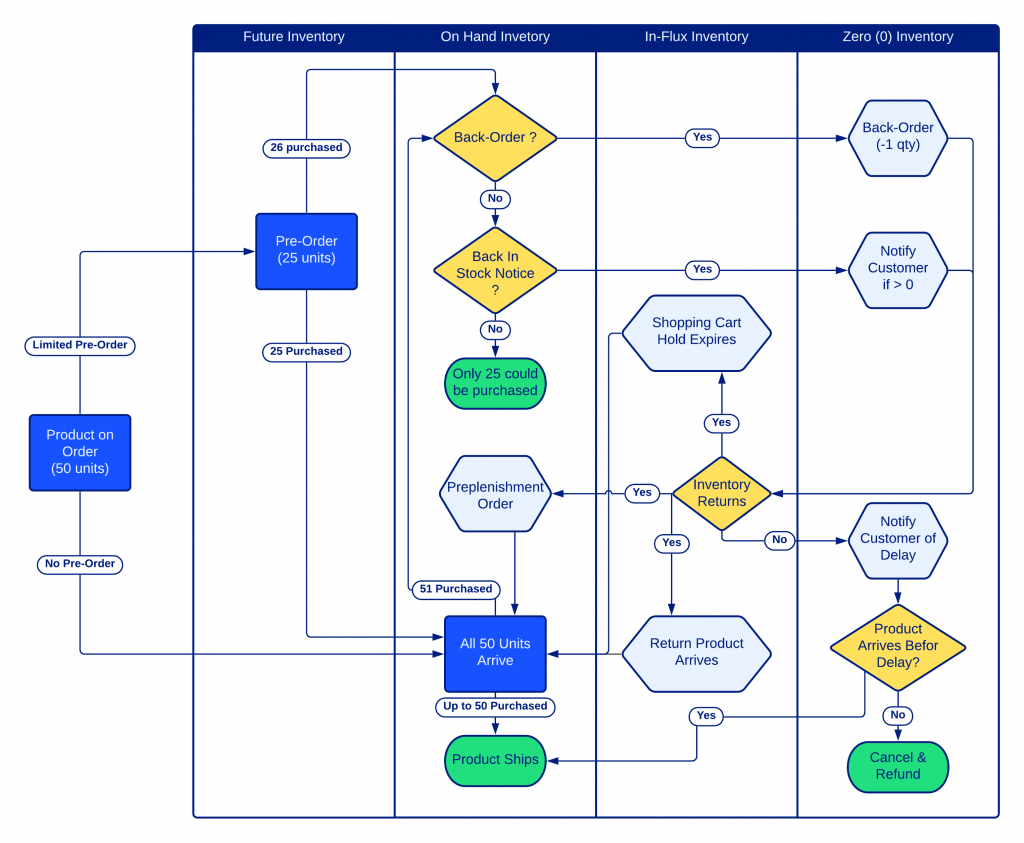

Back-Order and Pre-Order Decision path

In this article we have outlined the differences between back-order and pre-order but a practical case is always helpful. We have provided this decision path flow to help you navigate a real life scenario with all options available to a customer.

Bonus: BIS

Back In Stock (BIS) notifications are a great way to notify customers if an item, now out of stock which they are interested in, has available inventory in the future. BIS can be used in tandem with pre-order but often is not needed for back-order. This feature could be a great opportunity for a brand that has a limited inventory but a high cart-reservation rate or a high return rate. Additionally this is a great tool for a staple item that frequently gets a refreshed inventory.